3DOM Alliance Inc. (hereinafter “3DOM”) and noco-tech Inc. (hereinafter “noco-tech”) made presentations on two sets of research data related to the battery characteristics of lithium-ion secondary batteries and next-generation lithium metal secondary batteries equipped with the innovative separator, X-SEPA™, developed by 3DOM, at the 64th Battery Symposium held from November 28 through 30.

Presentation 1: Advancing Lithium Metal Battery Performance by Integrating an Ionic Liquid-based Electrolyte with a 3DOM Separator.

【Outline of the Results】

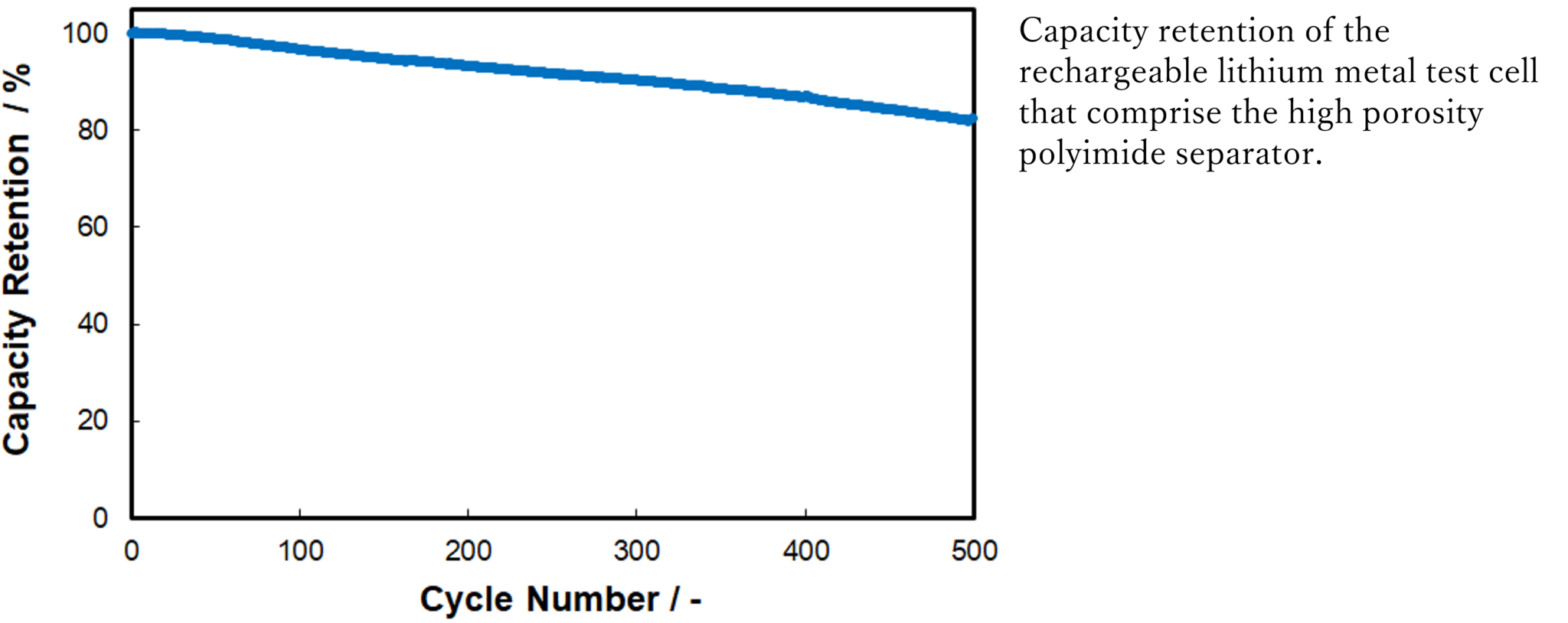

This study introduced ionic liquid-based electrolyte with high lithium salt concentration into a lithium metal secondary battery by using 3DOM separators and investigated battery characteristics such as lithium deposition and dissolution behaviour and charge-discharge cycle characteristics. Figure 1 shows the charge-discharge cycle characteristics of a lithium metal secondary battery with X-SEPA™, showing a capacity retention of more than 80% even after 500 cycles and excellent lifetime performance in terms of charge-discharge reversibility.

In addition, the use of ionic liquid-based electrolytes, which are more volatile and flame-retardant than conventional flammable organic solvent-based electrolytes, is expected to further improve battery reliability.

Presentation 2: Development of Long-Life Lithium Ion Secondary Batteries Using 3DOM Separators

【Outline of the Results】

Lithium-ion secondary batteries suffer from a significant reduction in battery life at high temperatures. The Company has been working on extending the service life of these batteries under 60℃ conditions by using a high-temperature-resistant electrolyte with a high boiling point that is resistant to high temperature environments. The special feature of this battery is that it combines a high viscosity, high temperature resistant electrolyte, which cannot be soaked up by ordinary polyolefin separators, with high seepage performance X-SEPA™.

In charge-discharge cycle tests currently underway at 60℃, it has been confirmed that batteries with X-SEPA™ and high temperature resistant electrolyte have a significantly improved capacity retention rate at approximately 3,000 cycles compared to batteries with general-purpose electrolyte and separator.

In addition, X-SEPA™ has a heat resistance of approximately 400℃ because it uses polyimide as the base material. Batteries that combine X-SEPA™ with high-temperature-resistant electrolyte maintain their separator function and do not suffer internal short-circuiting in endurance tests at 150℃ for one hour, where internal short-circuiting can occur with polyolefin separators because of shrinkage. The battery also maintained its charging and discharging performance without swelling because of the effect of the high temperature resistant electrolyte.

On the other hand, it was also confirmed that the battery has high charging performance in a 0℃ environment and can maintain cycle characteristics while maintaining the same charging conditions as at room temperature. These results show the possibility of realising lithium-ion secondary batteries that can be used in a wide range of temperatures, not only in high-temperature environment but also in low-temperature environment.

Conventional separators are made of polypropylene or polyethylene as raw materials and have the heat resistance temperature of around 120℃. On the other hand, the X-SEPA™ separator technology developed by 3DOM uses polyimide, which has high heat resistance at the 450℃ level and excellent affinity with high-temperature electrolyte. According to our research data, lithium-ion batteries that combine X-SEPA™ with a unique high-temperature resistant electrolyte have a service life up to five times longer than conventional batteries under high temperatures of 60℃, and further increases in service life are expected in the future. This is expected to lead to large-scale demands in India, Southeast Asia and other regions that have had problems with battery degradation in high-temperature environment. It is also expected to reduce the need for expensive cooling systems and space when designing battery packs, thus significantly reducing the cost of EV battery packaging.

X-SEPA™ can already be supplied at low cost with high quality thanks to the manufacturing process technology and production equipment that have been developed over more than eight years of research and development, and sample supply shipments to lithium-ion battery manufacturers worldwide have commenced from February 2023. Another key feature is that battery manufacturers can use the same raw materials and battery production facilities as before, making it possible to manufacture new high-performance lithium-ion batteries that are completely different from those of the past, with almost no need for new capital investment. Applications of X-SEPA™ are not limited to the automotive sector, but also meet diverse industrial needs, including data center, air mobility and marine applications such as vessels, and X-SEPA™ is expected to be a sustainable energy solution in a wide range of fields.

For enquiries:

Global PR, 3DOM Alliance Inc.

Email: pr@3dom.co.jp