Singapore and Tokyo, 24th April 2024 – noco-noco Inc. (NASDAQ: NCNC), (“noco-noco”), signed a Memorandum of Understanding with Binex Inc. Tokyo (“Binex”) to jointly develop agriculture-based carbon-credits.

Photo: Sorghum Cultivation in Thailand

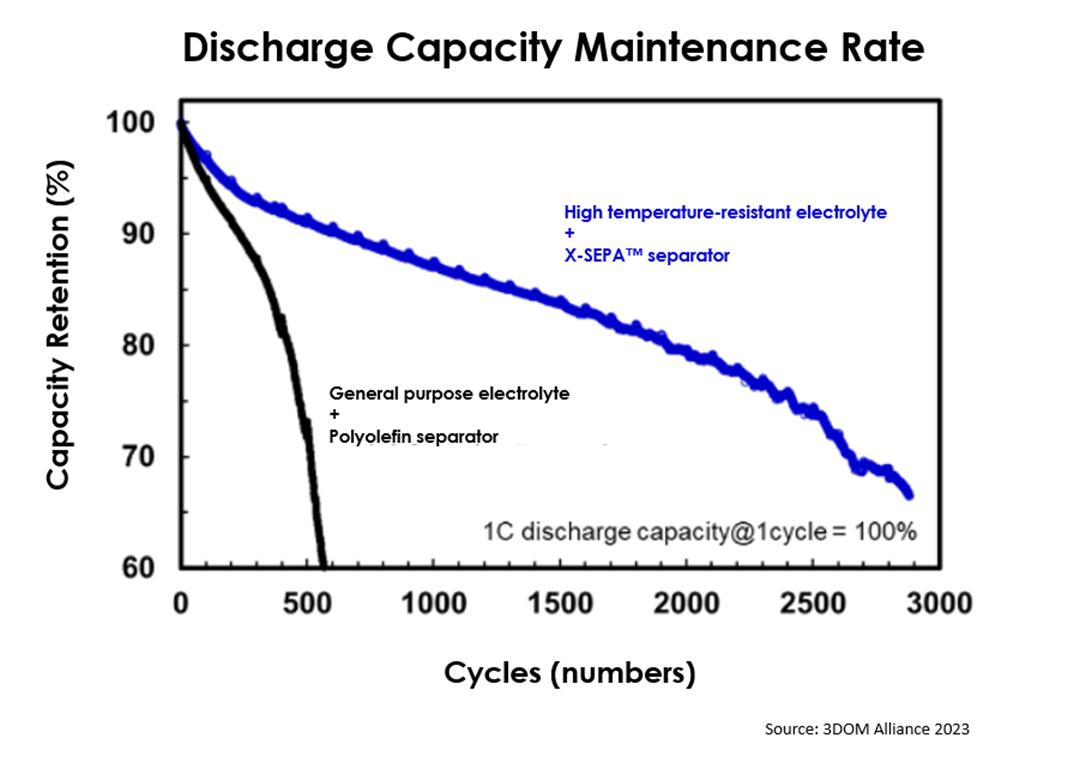

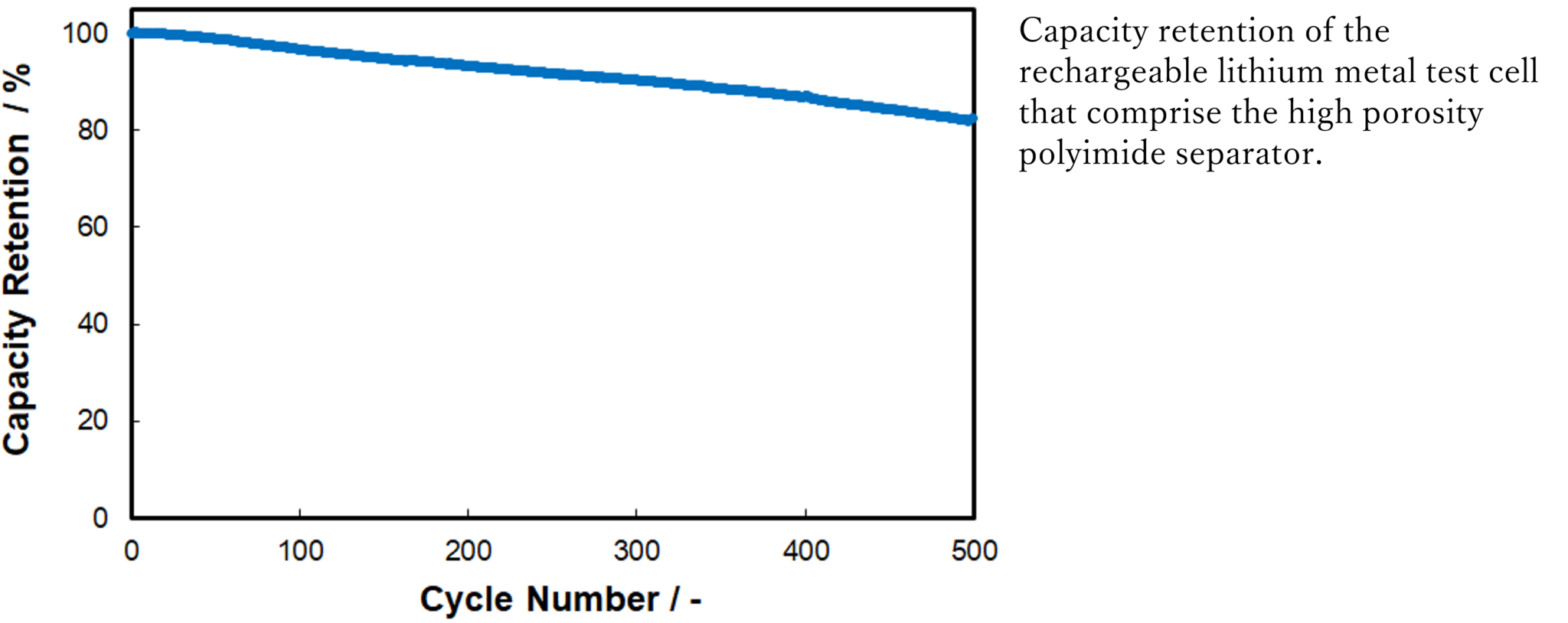

With its core mission in climate action to reduce carbon emissions, noco-noco, apart from its X-SEPA™ separator technology that extends lithium-ion battery life by approximately five times, also collaborates with partners to develop carbon credits. Currently, with thousands of hectares of nature-based deforestation credits under development in Papua New Guinea, noco-noco seeks to diversify into agriculture-based carbon credits by collaborating with Binex.

Binex is currently engaged in advancing the production of biofuels by cultivating sorghum, a member of the Gramineae family. The specific variety of sorghum used boasts high yields, capable of generating substantial biomass. Developed through collaborative research with the University of Tokyo, Binex aims to revolutionize the biofuel industry with this innovative approach. While conventional grain-type sorghum has a biomass of 40 to 60 tons/hectare/year , the types of sorghum that Binex uses have yields of over 250 tons/hectare/year .

In the face of escalating climate challenges, Binex’s sorghum project aligns with multiple United Nations Environmental, Social, and Governance (ESG) goals, including enhancing food security, reducing carbon emissions, improving soil health, and boosting farmers’ livelihoods. Sorghum, known for its resilience, thrives in marginal lands, enhancing soil quality. Utilizing sorghum stalks and leaves for biofuel production offers an eco-friendly alternative to oil and coal, complementing its traditional food cultivation purpose. This innovative initiative is poised to generate carbon credits through significant soil carbon sequestration during cultivation.

Armed with sorghum cultivation data from various countries and 10,000 hectares’ worth of sorghum seeds currently in stock and ready to be deployed, Binex will embark on large-scale cultivation soon. Cultivation was initiated in Thailand last year (See photo in article) and Binex plans to begin cultivation in Australia later this year.

Sorghum, with its deep roots and resilient components resistant to degradation, offers a tangible opportunity for soil carbon sequestration. Historically, estimating soil carbon storage during crop cultivation has been challenging due to its susceptibility to decomposition and variability based on land conditions. By prioritizing persistent components with enduring stability spanning hundreds or even thousands of years, this initiative is poised to establish the credibility and permanence necessary for high-quality carbon credits.

Studies by Binex have shown that through its lignite content, only 18 to 20 tons of carbon per hectare can be sequestered and maintained without degradation over an extended period. Further research is underway to increase carbon capture content, such as non-tillage cultivation and the use of bacteria for carbon capture, and it is projected that more carbon can be sequestered by combining these methods. Through methods like cultivation in root boxes and measurement of actual root mass, Binex aims to accurately quantify the carbon content within these roots progressing to project root mass in large-scale cultivated areas. By focusing on the carbon sequestered in the persistent components of the root, Binex will work towards the development of GHG sequestration and the production of high-quality carbon credits.

Mr. Masataka Matsumura, CEO of noco-noco, conveyed his excitement about the partnership, saying, “We’re thrilled to collaborate with Binex as we advance our mission to decarbonize and provide enhanced solutions with quality carbon credit offerings to our customers in the EV and battery manufacturing sector seeking to decarbonize.”

ⅰBased on test results commissioned by Binex.

ⅱBased on test results commissioned by Binex.

ⅲData from research papers and hearings with specialists are referenced.

ⅳQuantity of persistent components in roots when biomass is harvested at a rate of 200 tons/hectare.

For media inquiries, please email:

mailto: contactus@noco-noco.com

Read more about noco-noco:

https://noco-noco.com

Read more about Binex

https://binex.jp/en/

For more about Binex news release

https://binex.jp/en/home#news

Binex and Nissan Collaboration in supplying sorghum-derived bioethanol fuel for stationary power generation

About noco-noco Inc:

noco-noco Inc. (Nasdaq: NCNC) is a technology solutions provider working to accelerate the global transformation to a decarbonized economy. With its focus on commercializing innovative battery

technology, the revolutionary X-SEPA™ technology, a separator and electrolyte battery technology developed in Japan forms the core of the technology. X-SEPA™ lengthens battery life and provides a high level of thermal stability by enabling batteries to have high heat-resistant performance without compromising performance at low temperatures. noco-noco aims to address sustainability by enhancing the economic life of batteries for 1st and 2nd life use while minimizing resource wastage to provide affordable and sustainable energy storage solutions.

About Binex Inc:

Binex was established to earnestly address food, environmental, and energy issues and construct a value chain for biofuel. Binex aims to breed and cultivate sorghum varieties that sequester large quantities of carbon dioxide during growth; supply sorghum grain as a foodstuff; produce and supply biofuel from sorghum residue such as leaves and stalks; provide fuel cells that use biofuel as a hydrogen carrier; utilize biofuel in semiconductor manufacturing, fuels for internal combustion engines, and petrochemical raw materials; and develop additional applications, including chemical products that replace fossil fuels with biomass-derived materials.

Safe Harbor Statement:

This press release contains forward-looking statements within the meaning of section 27A of the U.S. Securities Act of 1933, as amended (the “Securities Act”), and section 21E of the U.S. Securities Exchange Act of 1934 (“Exchange Act”) that are based on beliefs and assumptions and information currently available to noco-noco. In some cases, you can identify forward-looking statements by the following words: “may,” “will,” “could,” “would,” “should,” “expect,” “intend,” “plan,” “anticipate,” “believe,” “estimate,” “predict,” “project,” “potential,” “continue,” “ongoing,” “target,” “seek” or the negative or plural of these words, or other similar expressions that are predictions or indicate future events or prospects, although not all forward-looking statements contain these words. Any statements that refer to expectations, projections, or other characterizations of future events or circumstances, the markets in which noco-noco operates as well as any information concerning possible or assumed future results of operations of noco-noco, are also forward-looking statements. These statements involve risks, uncertainties, and other factors that may cause actual results, levels of activity, performance, or achievements to be materially different from those expressed or implied by these forward-looking statements. Although noco-noco believes that it has a reasonable basis for each forward-looking statement contained in this communication, noco-noco cautions you that these statements are based on a combination of facts and factors currently known and projections of the future, which are inherently uncertain. noco-noco cannot assure you that the forward-looking statements in this communication will prove to be accurate. These forward-looking statements are subject to a number of risks and uncertainties, including, among others, the impact of the global pandemic like COVID-19, the outcome of any potential litigation, government or regulatory proceedings, and other risks and uncertainties. There may be additional risks that noco-noco presently does not know or that noco-noco currently believes are immaterial that could also cause actual results to differ from those contained in the forward-looking statements. In light of the significant uncertainties in these forward-looking statements, you should not regard these statements as a representation or warranty by noco-noco and its respective directors, officers or employees or any other person that noco-noco will achieve their objectives and plans in any specified time frame, or at all. The forward-looking statements in this press release represent the views of noco-noco as of the date of this communication. Subsequent events and developments may cause those views to change. However, while noco-noco may update these forward-looking statements in the future, there is no current intention to do so, except to the extent required by applicable law. You should, therefore, not rely on these forward-looking statements as representing the views of noco-noco as of any date subsequent to the date of this communication.